Dynamic Modulus Test

GCTS offers multiple testing solutions to perform dynamic modulus tests on asphalt pavement specimens. These include the economical AMPT-15, the advanced ADM-100, and the versatile APT-100.

The Asphalt Mixture Performance Tester (AMPT-15) was designed to easily perform a full range of asphalt tests according to AASHTO, ASTM, and NCHRP standards. The small profile of the mobile cart and economical price point makes it an ideal system for testing laboratories and universities around the world. The AMPT-15 is designed to maximize the test efficiency through intuitive design and innovative software. This system can be upgrades with a variety of accessories to perform a full range of asphalt tests.

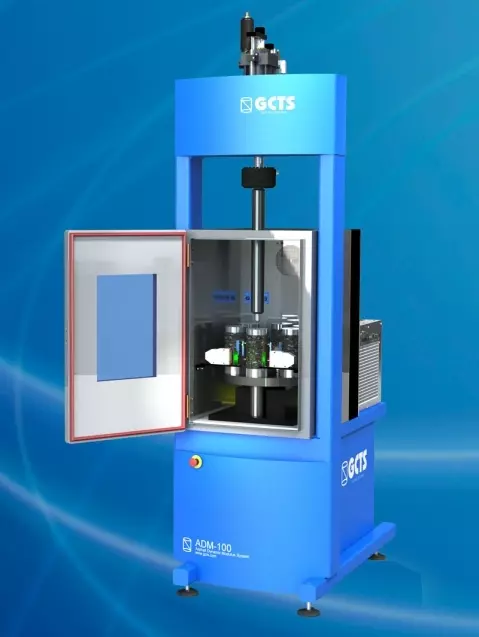

The Automated Dynamic Modulus Testing System (ADM-100) is the most productive dynamic modulus testing system on the market. With its advanced automation process, a complete Master Curve can be generated for up to six specimens in less than two days. Inside the GCTS environmental chamber is a rotating table and two non-contact optical micrometer measurement sensors. The table has room for size specimens and rotates automatically, allowing the specimens to be positioned under the loading piston without any input from the operator. In addition, the specimens rotate into the range of the optical micrometer sensors, so measurements can be made without the hassle of moving LVDTs. By including this automatic rotating table, the door to the environmental chamber never needs to be opened, drastically reducing the amount of time needed to perform the test. This also allows the system to perform without any user intervention, so the test can continue to run without the operator in the lab.

The Asphalt Pavement Tester (APT-100) is a very affordable device that can perform a complete assortment of testing procedures for asphalt specimens. The equipment was designed in a modular fashion, which allows the user to quickly set up different tests. This system is capable of performing Dynamic Modulus, Resilient Modulus, Beam Fatigue, Direct Tension, and a number of other tests. All pieces necessary to perform all the tests are incorporated into a single unit, thereby optimizing laboratory space. This system also includes a state-of-the-art dynamic actuator that can apply loads at up to 70 Hz with minimal friction, and advanced software that allows the system to deliver precise results. The system also includes a full environmental chamber that allows multiple specimens to be cooled or heated to the correct testing temperature, speeding up the rate at which a complete master curve can be generated and verified by multiple specimens.

Relevant Standards

- AASHTO T 342 Standard Method of Test for Determining Dynamic Modulus of Hot-Mix Asphalt Concrete Mixtures

- ASTM D3497 Standard Test Method for Dynamic Modulus of Asphalt Mixtures

- EN 12697-25 Bituminous mixtures. Test methods for hot mix asphalt. Cyclic compression test.

AMPT-15

HIGHLIGHTS

- 19 kN static load capacity

- 17 dynamic load capacity

- 70 Hz maximum testing frequency

- 50 mm actuator stroke

- -10°C to +70°C temperature control

- 0.2% temperature control accuracy

- 250 kPa confining pressure capacity

- Available accessories to perform the following tests:

- Dynamic modulus

- Flow time

- Flow number

- Resilient modulus

- Beam flexural fatigue

- Indirect tension

- Semi-circular bending

- Texas Overlay

- Direct tension (SVECD)

- Meets the following testing standards:

- AASHTO T 378

- AASHTO T 342

- AASHTO R 84

- NCHRP 9-19

- NCHRP 9-29

TRANSDUCER SPECIFICATIONS

- 22 kN load cell

- 345 kPa pressure sensor

- 50 mm actuator LVDT

- ±1 mm displacement sensor

- -50°C to +250°C temperature sensor

ADM-100

HIGHLIGHTS

- Generate full master curve for six specimens in two days

- Non-contact deformation sensors with 0.5 micron repeatability

- 85 kN dynamic load capacity

- 100 kN static load capacity

- 100 mm axial stroke

- 1200 mm vertical opening

- 600 mm horizontal opening

- Temperature control from -15°C to 70°C

APT-100

HIGHLIGHTS

- Economical solution for advanced asphalt testing

- 100 kN static axial load capacity

- 85 kN dynamic axial load capacity

- 70 Hz maximum loading frequency

- 100 mm actuator stroke

- Precise, accurate, quiet and compact

- Temperature control from -15 °C to +60 °C

- Available accessories to perform the following tests:

- Dynamic modulus

- Flow time

- Flow number

- Resilient modulus

- Beam flexural fatigue

- Indirect tension

- Semi-circular bending

- Texas Overlay

- Direct tension (SVECD)