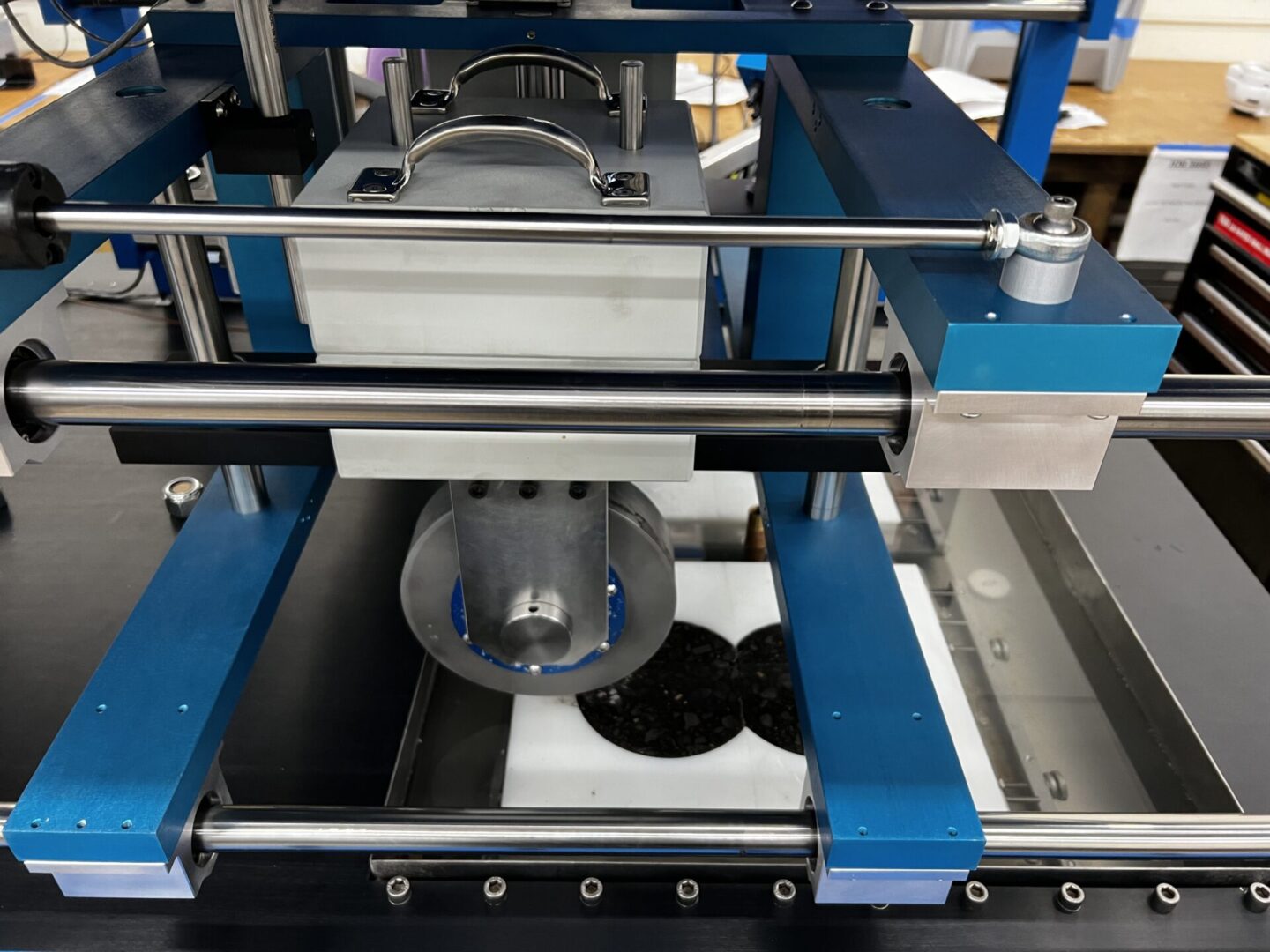

Hamburg Wheel-Tracking

The GCTS Hamburg Wheel-Tracker directly applies the vertical load to the specimens during testing. Most other systems use a weighted cantilever arm to apply the vertical load, resulting in excessive vibrations and an inability to accurately measure the vertical load. The GCTS system instead utilizes a mobile frame to keep the load directly above the loading wheel and dampeners to prevent vibration of the frame during horizontal movement. With this setup, you can be confident that the load stays at 705N (±4.5N) for the duration of the test.The HWTT-100 meets all the specifications of AASHTO T 324 and EN 12697-22. Tests can be performed with either stainless steel or rubberized testing wheels, which can be interchanged as needed. This system utilizes a water bath for temperature control of the two specimens, which can be tested simultaneously.

HWTT-100

HIGHLIGHTS

- 705N ± 4.5N constant load

- Load applied directly above the specimens

- Water bath for temperature control up to 70°C

- Temperature control ±0.5°C

- Stainless steel or rubberized wheels

- Two wheels for simultaneous testing of two specimens