Specimen Core Drilling

The GCTS Specimen Core Drill provides the first step to preparing test specimens for a variety of material characterization tests. These core drills are able to handle heavy-duty tasks by using a large range of spindle speeds to provide optimum performance regardless of the properties of the material being cored. Some drills include stress and stroke control to optimize the feeding rate when coring material that is not homogenous.

GCTS also offers Specimen End Grinders, and a Specimen Verification Kit to fully prepare a cylindrical rock specimen for testing.

Relevant Standards

ASTM D4543 Standard Practices for Preparing Rock Core as Cylindrical Test Specimens and Verifying Conformance to Dimensional and Shape Tolerances

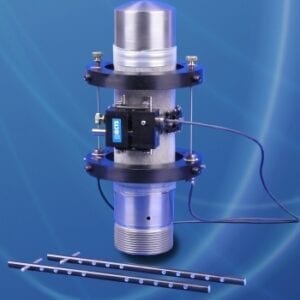

RCD-500

HIGHLIGHTS

- Electric motor with adjustable spindle speeds from 300 through 2,000 RPM.

- The drilling rate is controlled by load/stress or displacement rate, eliminating the tendency for hard aggregates to move.

- Servo-controlled feed rate with 300-mm automatic travel.

- Rigid column drill support frame to eliminate ridges on the specimen.

- Wide variety of Coring Barrels to choose from.

- 5 HP electric motor.

POWER REQUIREMENTS

- 230-460 VAC/3P/60 Hz or 400 VAC/3P/50 Hz