Beam Flexural Fatigue

The GCTS Beam Fatigue Testing Equipment was designed to test the fatigue life of a beam of Hot Mix Asphalt. This test is performed through the use of a four-point loading jig to apply a repetitive load to a prismatic specimen under constant stress or constant strain conditions. When used with a GCTS Servo Controller, the included software can perform the test according to the AASHTO, ASTM and EN standards while also allowing the user to perform custom loading conditions for research purposes. This software allows the operator to automatically obtain the fatigue life parameters, including initial stiffness, maximum tensile stress/strain, flexural stiffness, phase angle, dissipated energy per cycle, cumulative dissipated energy to failure, and number of cycles to failure.

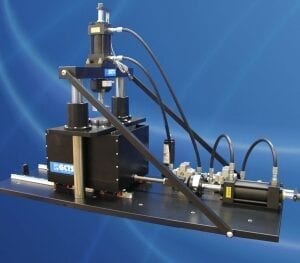

The standard beam fatigue loading jig requires a suitable load frame to provide the repeated loading. GCTS also offers pneumatic or hydraulically-powered loading jigs for use anywhere in a laboratory.

As a complete solution, GCTS offers the BFFS-P, which includes the pneumatic loading jig, a fiberglass environmental chamber for temperature control, and a servo-controller and data acquisition system with a battery backup system to ensure the test will continue during a power outage.

Relevant Standards

- AASHTO T321 Standard Method for Determining the Fatigue Life of Compacted Asphalt Mixtures Subjected to Repeated Flexural Bending

- EN 12697-24 Bituminous mixtures. Test methods. Resistance to fatigue

- EN 12697-26 Bituminous mixtures. Test methods. Stiffness

BFFS-H

HIGHLIGHTS

- Hydraulic, stand-alone test system

- 4-point loading jig

- ± 1 mm range LVDT sensor

- ± 5 kN load capacity

- 60 Hz maximum loading frequency

- 75mm x 75mm x 381mm specimen dimensions

- Includes environmental chamber for -15C to +70C

BFFS-P

HIGHLIGHTS

- Economical, stand-alone test system

- 4-point loading jig

- ± 1 mm range LVDT sensor

- ± 5 kN load capacity

- 10 Hz maximum loading frequency

- 75mm x 75mm x 381mm specimen dimensions

- Includes temperature stability chamber for 21C

- Requires 800 kPa compressed air supply

BFFA

HIGHLIGHTS

- 4-point loading jig

- ± 1 mm range LVDT sensor

- ± 5 kN load capacity

- 60 Hz maximum loading frequency

- 75mm x 75mm x 381mm specimen dimensions

- Temperature rating: -15C to 70C (non-condensing)

- Requires a suitable load frame or upgrade to pneumatic / hydraulic loading jig

- Requires a suitable environmental chamber for temperature stability