Rock On-Specimen Measurement

GCTS offers advanced solutions for on-specimen measurement of various properties.

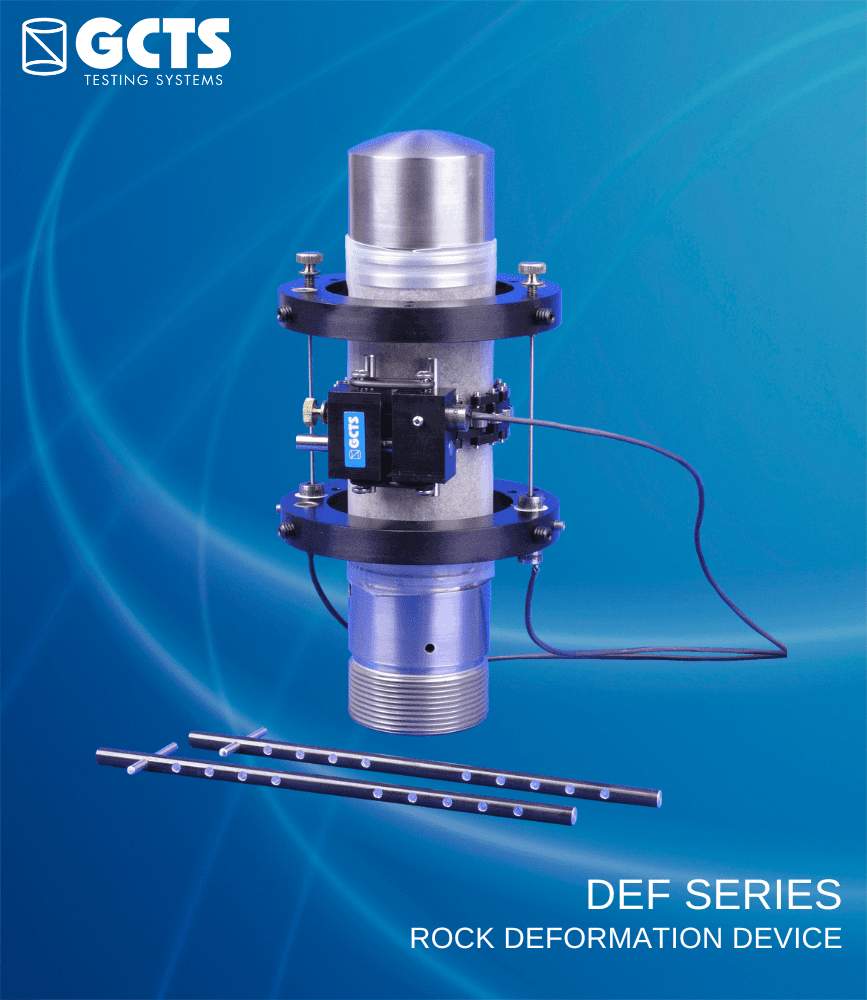

The DEF-5000 Rock Deformation Devices measure axial and average radial strain directly on specimens using axial LVDT holder rings and a radial chain device. Suitable for specimens with diameters between 25 mm and 150 mm, these devices work within high-pressure triaxial cells at varying temperatures. They determine elastic constants like Young’s modulus and Poisson’s ratio and can analyze post-failure inelastic strains. When integrated with GCTS servo control units and load frames, they enable direct control of axial or radial strain.

The DEF-CAN Diametral Deformation Device enhances the DEF-5000 by replacing the radial chain with a cantilever bridge, measuring radial strain in two planes. It features a single ring with four sensor arms, each equipped with strain gauges, to measure diametral deformations. This setup is easily adjustable for various specimen diameters and is compatible with high-pressure, high-temperature triaxial cells or unconfined settings.

GCTS CDM fixtures measure parameters across cylindrical specimens using a reusable membrane that withstands pressures up to 210 MPa and temperatures up to 200°C. These membranes include lateral ports for sensor insertion, allowing simultaneous measurement of different physical properties, including axial sensors. Customizable membranes with various port configurations are available.

DEF-5000

HIGHLIGHTS

- Measures axial and lateral strain directly on the test specimen

- Available for specimens with an initial diameter from 25 mm to 150 mm

- Includes two axial sensor supports and one circumferential chain device

- Can be used for unconfined or confined testing

- Uses three LVDTs for ease of operation. LVDTs can be provided for high-temperature, high-pressure testing

- Very easy to set up and use

DEF-CAN

HIGHLIGHTS

- Direct measurement of specimen diametral deformation

- Available for specimens with an initial diameter from 25 mm to 150 mm

- Measures diametral changes at two points perpendicular to each other

- Can be used for unconfined or confined testing

- Sturdy construction to prevent device damage

- Fast and easy setup

- Can be used with GCTS Reusable Membranes for on-specimen radial strain measurements while performing other cross-diametral measurements

CDM

HIGHLIGHTS

- Ideal for investigating anisotropic behavior, hydraulic fracturing, proppant testing, etc.

- Three-Dimensional measurements (Axial and Diametral Measurements at two orthogonal directions)

- Available for specimens with an initial diameter from 25 mm to 150 mm

- Can be used inside a GCTS Triaxial Cell at high confining pressures up to 210 MPa (30,000 psi) and up to 200 ˚C

- Can be used with the DEF-CAN devices to directly measure radial strain

- Options to measure P and S Wave Velocities, Acoustic Emissions, Permeability, Resistivity and mid-plane pore pressure measurements

- Sturdy construction to prevent device damage